What is HiPowAR?

The direct and highly efficient conversion of ammonia into useful work or drive energy is the main objective of the EU project "HiPowAR" (EU Grant Agreement No. 951880). For the first time, proof of concept is being provided for a completely new type of energy converter based on the total oxidation of the synthetic, carbon-free fuel NH3 in a high-pressure membrane reactor.

HiPowAR grew out of the Campfire Alliance. German project partners are the coordinating Leibniz Institute for Plasma Science and Technology, Fraunhofer IKTS and the Center for Fuel Cell Technology. Companies and research institutions from Sweden and Italy are also involved.

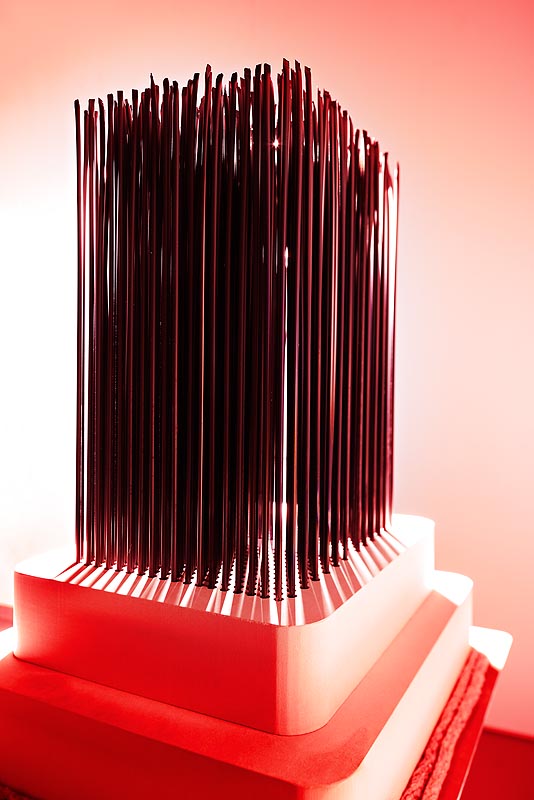

Analogous to the solid electrolyte fuel cell (SOFC - Solid Oxide Fuel Cell), the conversion takes place on an oxide ion-conducting membrane that only allows atmospheric oxygen from the ambient air to enter the reaction. In contrast to the fuel cell, however, in the HiPowAR concept this membrane is also conductive for electronic charge carriers; it is therefore referred to as a MIEC membrane (Mixed Ionic Electronic Conductor). Since the mixed conductivity results in an internal electrical short circuit of the solid electrolyte membrane, this MIEC membrane is permeable to oxygen (permeable to O2). This therefore enters the reaction chamber automatically at high temperature as long as the O2 partial pressure remains low there due to the O2-consuming reaction. However, the energy released during NH3 oxidation cannot be extracted as electrical work as in a fuel cell because of the internal short circuit. However, in the high-pressure membrane reactor, it leads to an automatic compression of the combustion gases to very high pressures and extreme temperatures, since the cooling air-nitrogen is missing.

Therefore, in the HiPowAR concept, similar to the conventional steam process, water (liquid/gaseous) is still added, thereby lowering the gas temperature and converting it into additional gas volume. Subsequently, conventional gas expanders (steam engine, steam turbine, natural gas expander, etc.) are used to convert the compressed product gas stream into expansion work.

The first calculations show that the available gas expansion work of the HiPowAR system allows a significantly higher efficiency than the best fuel cells. The electrical losses of the fuel cell are eliminated, as well as typical costly FC components (stacks, interconnectors, electrical interconnection, reformer, afterburner, etc.) of the usual fuel cells. Therefore, a significant cost reduction for subsequent commercial systems is expected. This is especially true for high power, since the power-normalized cost of commercial gas expanders (e.g., steam engines and steam turbines) decreases significantly with increasing power.

The HiPowAR concept simultaneously relies on the use of the carbon-free synthetic fuel ammonia (NH3). This is much easier to store than hydrogen, but it is also much more difficult to convert into useful work or drive energy. This is mainly due to the low flame propagation speed, which limits direct combustion in conventional turbines and engines. For this reason, support fuels are usually used, which can be dispensed with for the first time in the new HiPowAR concept.